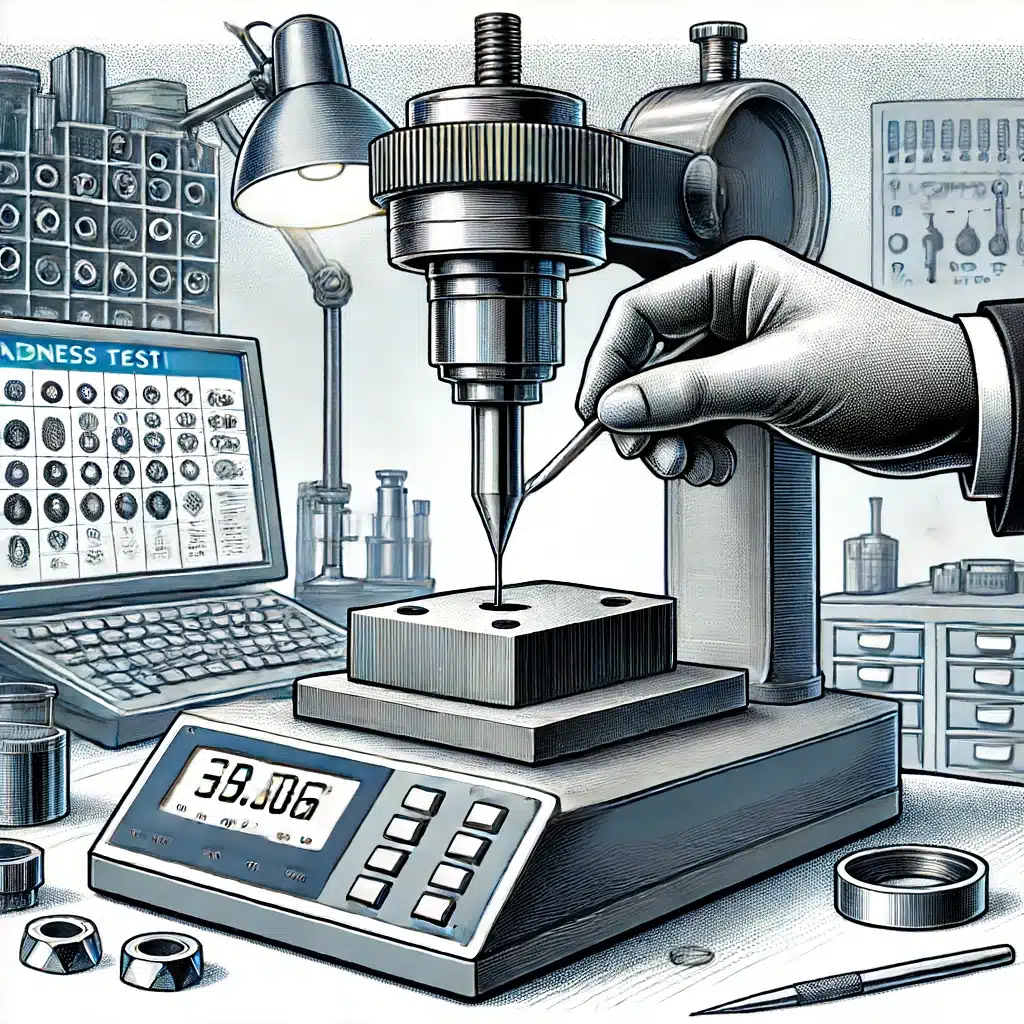

Hardness testing is a method used to determine the hardness of a material, which is a measure of its resistance to deformation, scratching, or indentation. This property is crucial in understanding how a material will behave under various conditions, such as pressure, impact, and wear.

What is Hardness Testing?

Hardness testing measures how well a material can resist being permanently deformed. There are several methods for testing hardness, but they all involve pressing a hard object (called an indenter) into the material and measuring the resulting indentation.

Why is Hardness Testing Important?

– Material Selection: Helps engineers choose the right material for a specific application.

– Quality Control: Ensures materials meet the required standards and specifications.

– Predicting Behavior: Provides insight into the material’s wear resistance and strength.

Common Hardness Testing Methods

1. Brinell Hardness Test:

– Method: A hard ball (usually made of steel or tungsten carbide) is pressed into the material under a specific load. The diameter of the indentation is measured.

– Applications: Suitable for testing metals with coarse structures, like cast iron.

2. Rockwell Hardness Test:

– Method: An indenter (either a diamond cone or a steel ball) is pressed into the material under a specific load. The depth of the indentation is measured.

– Scales: There are different scales (e.g., Rockwell A, B, C) for testing various materials, with the Rockwell C scale (HRC) being common for metals.

– Applications: Widely used for testing metals and alloys.

3. Vickers Hardness Test:

– Method: A diamond pyramid-shaped indenter is pressed into the material under a specific load. The diagonals of the resulting indentation are measured.

– Applications: Suitable for testing all types of materials, including metals, ceramics, and composites.

4. Knoop Hardness Test:

– Method: A diamond indenter with an elongated shape is pressed into the material under a specific load. The length of the indentation is measured.

– Applications: Ideal for testing brittle materials like glass and ceramics.

5. Shore Hardness Test:

– Method: A spring-loaded indenter is pressed into the material, and the hardness is read directly from a scale on the instrument.

– Applications: Commonly used for testing polymers, rubbers, and elastomers.