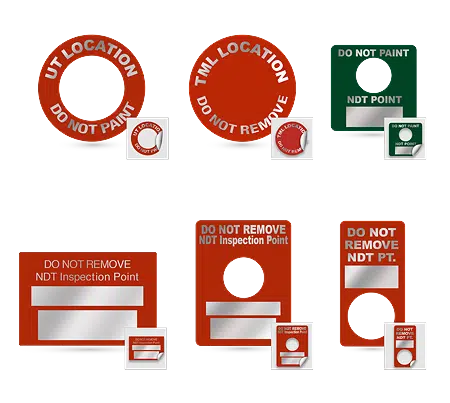

NDT Inspection Plugs

NDT Inspection Plugs engineered for monitoring Corrosion under Insulation (CUI) and mechanical integrity.

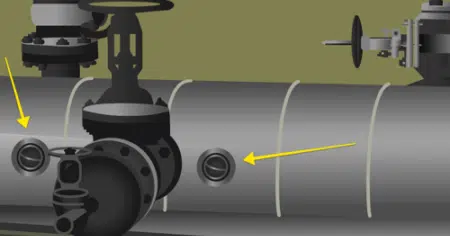

Removable inspection plugs allow repeat access to NDT Access points for EPA/OSHA inspection and testing.

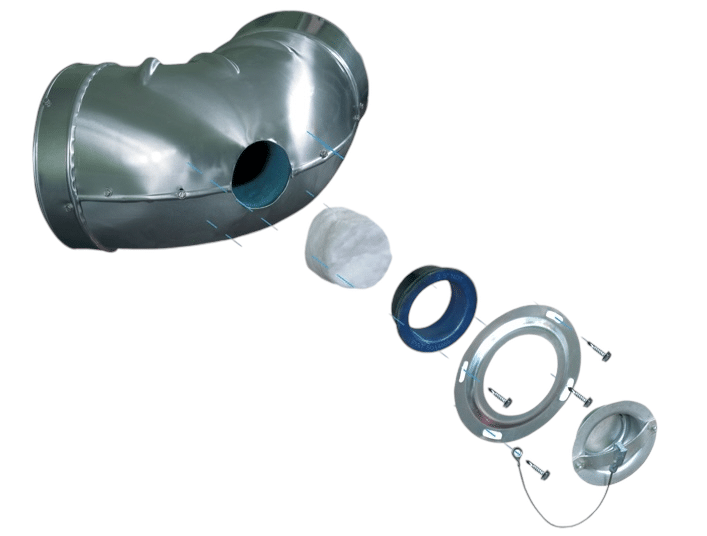

Inspection Plugs seal NDT access points with removable aluminum or stainless steel metal caps.

- Chemical and UV exposure protection

Inspection plugs are engineered for insulated pipe, pipelines, storage tanks, pressure vessels, petrochemical, oil and gas, steam and nuclear power generation facilities.

- Inspection for Corrosion Under Insulation (CUI).

- Ozone and weather UV resistant.

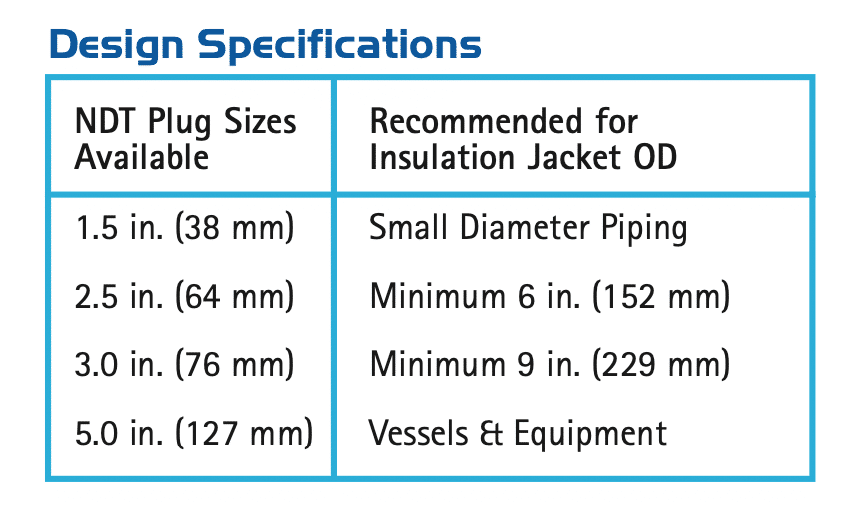

NDT Inspection Plug Sizes

Diameters: 1.5″ | 2.5″ | 3.0″ | 5.0″

(38 | 64 | 76 | 127 mm)

Note: NDT Plugs can be installed on smooth or corrugated insulated jacketing.

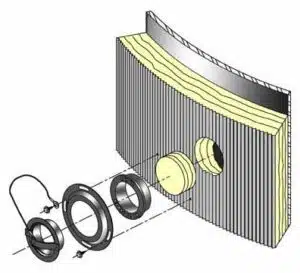

Locate and mark the insulation jacket where the inspection plug will be installed:

- Hole saws are best to penetrate the insulation jacket, cut a circumference equal to the plug to be installed.

- Use either tin snips or a holesaw to penetrate the insulation jacket with a diameter equal to the size of the Inspection Plug.

- Remove the insulation to expose the substrate for inspection.

- After inspection, re-insert the insulation or replace it with a high-density material.

- Insert the EPDM or Silicone Sleeve.

- Install the Inspection Plug Locking Ring and Lanyard if equipped.

- Insert the metal cap to create a seal

Note: Caulking around sleeve for cold weather applications recommended