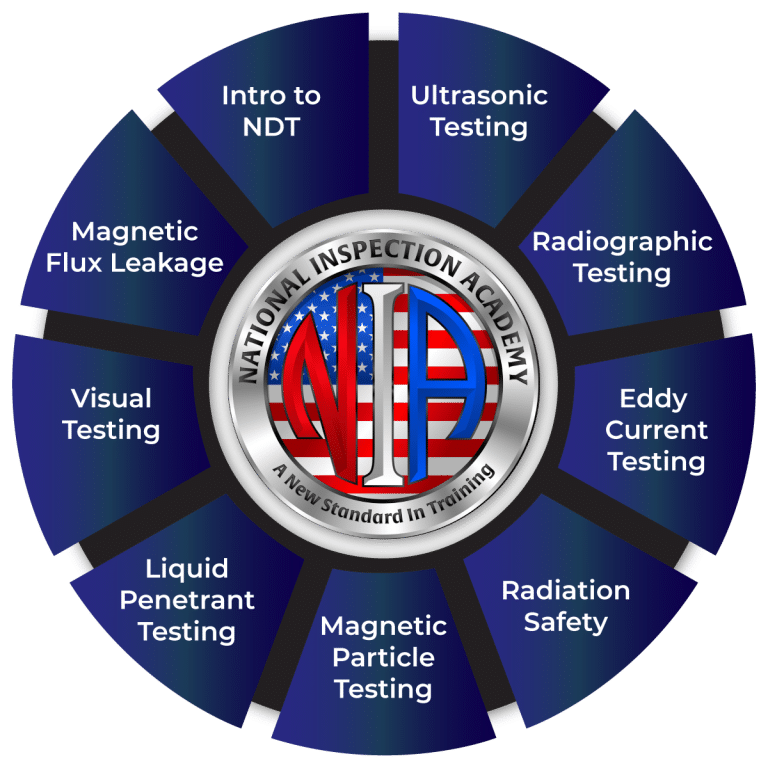

NIA’s NDT Career Program immerses students in the world of NDT, providing them with a robust training program which includes Level I and Level II training in seven highly sought after NDT methods as well as a full radiation safety training course. This level of education propels students into the...