Features and Benefits

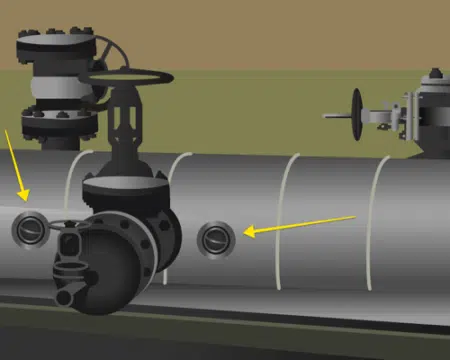

Nondestructive Testing (NDT) Plugs are engineered to allow repeat access for EPA/OSHA inspection and process safety management.

Plugs can be installed on insulated and non-insulated pipe, storage tanks, pressure vessels and petrochemical, oil and gas, steam and nuclear power generation facilities.

Engineered NDT2 inspection plugs consist of an elastomer sleeve, metal handle, metal cap, lanyard* and locking ring.

The elastomer sleeve consists of ethylene propylene (EPDM) or silicone (higher temps).

The metal caps can be 304 stainless steel or 5052 aluminum depending on the application.

* Note: lanyards are particularly useful in overhead conditions to prevent the cap from falling if dropped.

Regular access to pipes and equipment benefits areas of process safety management:

Safety

NDT inspection plugs allow inspectors to safely access the inside of insulated pipes and equipment without removing the insulation. This helps to ensure the safety of the piping system.

Accuracy

NDT inspection plugs help to ensure that thickness measurements are accurate. They also standardize the location of thickness measurements, which helps to protect the integrity of inspection data.

Time

NDT inspection plugs reduce the time required for periodic inspections and tests. Once installed, access often.

Corrosion

NDT inspection plugs provide a seal that can help protect against corrosion under insulation (CUI), chemical and UV exposure.