Non-Destructive Testing (NDT) evaluates the properties of materials, components, or systems without causing damage. NDT Inspection Plugs (Seals / Ports) ensure the safety, reliability, and longevity of equipment and structures while allowing continuous monitoring.

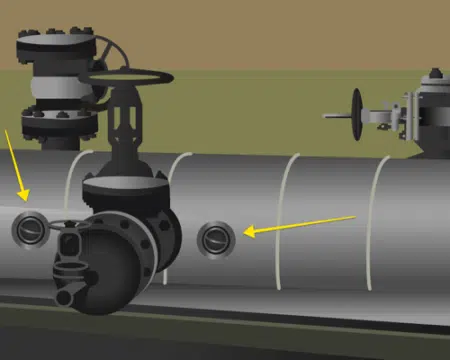

1. Access Point for Inspection: The plug provides an access point for technicians to perform various NDT procedures. Depending on the type of test being conducted, this might involve inserting probes, sensors, or other equipment through the plug.

2. Seal and Insulate: Once inspections are done, the plug can be closed to maintain the integrity of the system or structure it’s installed on. This often means it needs to have properties such as resistance to high temperatures, certain chemicals, or pressure to ensure the system remains safe and functional.

3. Repeated Use: A key feature of NDT inspection plugs is that they can be opened and closed multiple times.

This allows for regular inspections over the lifespan of a structure or piece of equipment without the need to create new access points each time.

4. Minimize Heat Loss: In thermal systems or those with insulation, an NDT inspection plug can be designed to minimize heat loss.

After the inspection is done, the plug is replaced, ensuring that the insulation’s efficiency isn’t compromised.

5. Safety: The plug should be designed to ensure the safety of the technicians. This might involve features that prevent accidental opening or ensuring that, when opened, there aren’t risks associated with sudden releases of pressure or exposure to harmful substances.