Testing + Inspection

In-Line Inspection (ILI) verification is a process used in pipelines to ensure their safety and integrity. By detecting issues early, companies can prevent leaks or ruptures, which can cause environmental damage and be very costly to repair.

Like sending a robotic doctor through a pipeline to check for health issues and collect data, which engineers then analyze and verify to ensure the pipeline is in good condition.

What is In-Line Inspection?

Over time pipelines develop issues like cracks, corrosion (rust) or dents. To check for these problems without digging up the pipeline, companies use a special tools called “smart pigs” that travels through the pipeline.

Smart Pigs?

The smart pig is an inspection device equipped with sensors that can detect various issues inside the pipeline as it travels through including:

- Magnetic Flux Leakage (MFL): Detects metal loss due to corrosion or cracks.

- Ultrasonic Testing (UT): Measures the thickness of the pipeline walls.

- Caliper: Detects dents or deformations in the pipeline.

Verification Process

Engineers then analyze this data to verify the condition of the pipeline.

Data Analysis:

- Engineers look at the data collected by the smart pig.

- They identify areas with potential issues.

Field Verification:

- Engineers physically inspect the pipeline at locations where the smart pig found potential problems.

- They might dig up sections of the pipeline to confirm and repair any issues.

Repair and Maintenance:

- If issues are found, they are fixed to prevent any future problems.

- The pipeline is then monitored regularly to ensure it remains in good condition.

Testing + Inspection

The EPA is involved in regulating various aspects of the environment, including water quality, air quality, hazardous waste, and more. When it comes to pipelines, the EPA’s jurisdiction primarily covers areas related to pollution and environmental protection.

Here’s a brief overview of some regulations and guidelines related to pipeline inspections that the EPA may be involved in:

- Clean Water Act (CWA): Pipelines near or crossing bodies of water must adhere to regulations protecting water quality. Any discharge of pollutants must be controlled and monitored.

- Clean Air Act (CAA): This may affect pipelines by regulating the emissions from any equipment used in the process, such as compressor stations.

- Resource Conservation and Recovery Act (RCRA): This could be applicable to pipelines, as it regulates the management of hazardous and non-hazardous solid waste.

- Spill Prevention, Control, and Countermeasure (SPCC) Rules: These rules apply to facilities that store, handle, or transport oil. They require a detailed plan for preventing oil spills, controlling a spill should one occur, and outlining countermeasures to minimize the impact on the environment.

- Emergency Planning and Community Right-to-Know Act (EPCRA): Pipelines carrying hazardous materials must comply with regulations regarding community notification and emergency response planning.

- National Environmental Policy Act (NEPA): Any major federal action, including permitting for pipelines, requires an analysis of environmental impacts, alternatives, and mitigation measures.

- Toxic Substances Control Act (TSCA): This might apply to pipelines carrying certain chemicals and requires compliance with regulations related to reporting, record-keeping, and testing.

- Pipeline and Hazardous Materials Safety Administration (PHMSA): While not part of the EPA, PHMSA is a key federal agency overseeing pipeline safety regulations, including inspection and maintenance standards. It’s important to note that EPA regulations would work in conjunction with PHMSA rules.

Keep in mind that regulations can vary greatly depending on the type, location, and content of the pipeline. State and local regulations may also apply, and consultation with relevant agencies and legal experts is generally advisable to ensure full compliance.

#pipelines #epa #inspections

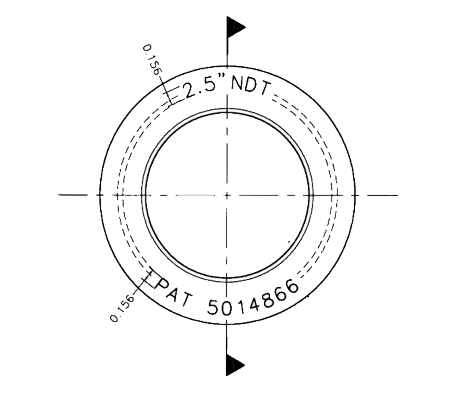

NDT Insulation Plug Installation