NDT Inspection Plugs

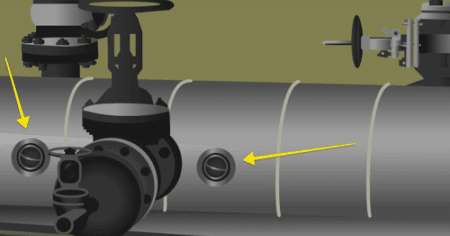

TML Point Labels

NDT Inspection Plugs engineered for monitoring Corrosion under Insulation (CUI) and mechanical integrity.

NDT inspection plugs seal EPA and OSHA access testing points.

- Prevent Chemical and UV exposure

Inspection Plugs come standard with removable aluminum or stainless steel metal caps for repeat access.

NDT Inspection plugs are engineered to be removable after installed for repeat access.

Removable NDT plugs allow access for regular, scheduled – and unscheduled – Nondestructive Testing.

Engineered for insulated pipe, pipelines, storage tanks, pressure vessels at petrochemical, oil and gas, steam and nuclear power generation facilities.

- Inspection for Corrosion Under Insulation (CUI).

- Ozone and weather UV resistant.

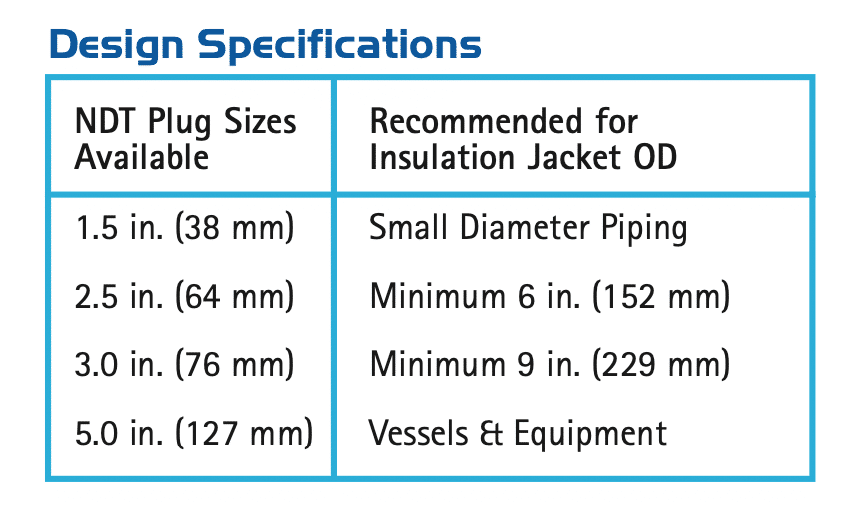

NDT Inspection Plug Sizes

Diameters: 1.5″ | 2.5″ | 3.0″ | 5.0″

(38 | 64 | 76 | 127 mm)

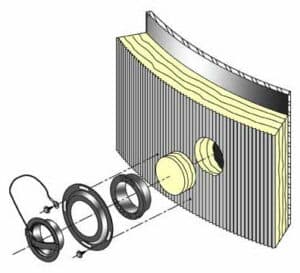

Our NDT Plugs can be installed on smooth or corrugated insulated jacketing.

Locate and mark the insulation jacket where the inspection plug will be installed:

- Hole saws are best to penetrate the insulation jacket, cut a circumference equal to the plug to be installed.

- Use either tin snips or a holesaw to penetrate the insulation jacket with a diameter equal to the size of the Inspection Plug.

- Remove the insulation to expose the substrate for inspection.

- After inspection, re-insert the insulation or replace it with a high-density material.

- Insert the EPDM or Silicone Sleeve.

- Install the Inspection Plug Locking Ring and Lanyard if equipped.

- Insert the metal cap to create a seal

Note: Caulking around sleeve for cold weather applications recommended